PRODUCT DETAILS

blast furnace slag and casting waste to prepare inorganic fiber

Introduction to the process of preparing inorganic fibers from blast furnace slag and casting waste:

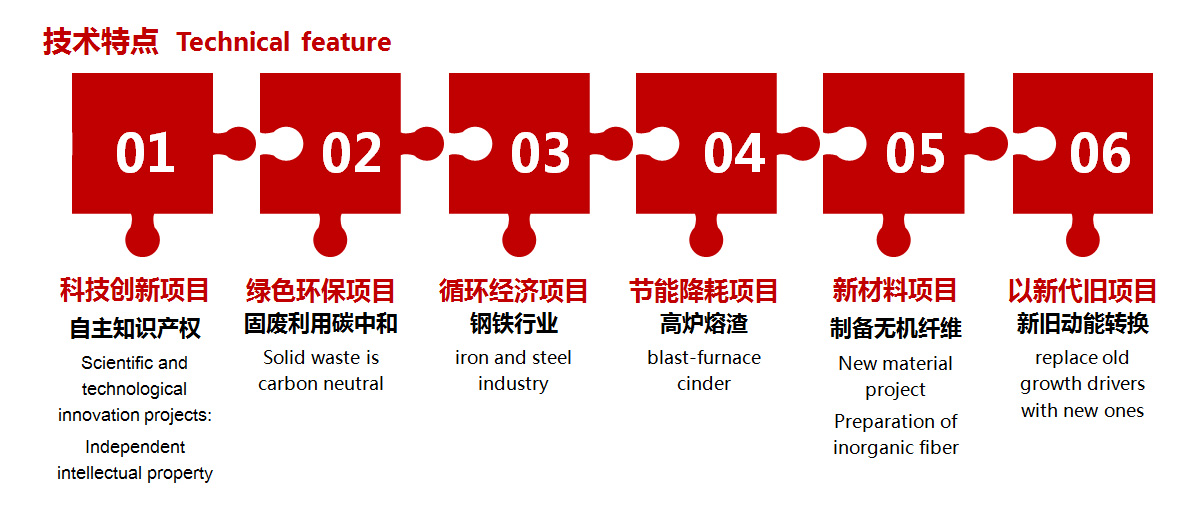

Company proprietary technology

The first is to solve the problem of blast-furnace slag discharge and disposal that restricts the development of iron and steel enterprises and realize resource utilization;Steel companies benefit.

The second is to solve the problem of high energy consumption and high pollution of the whole chain of rock wool industry;Society benefits.

Third,is to solve the problem of large market demand for rock wool but limited by environmental protection,limited production and high cost;The market benefits.

Fourth,it fills a number of gaps at home and abroad,which is of great significance for circular economy and sustainable development,promoting the utilization of solid waste resources,energy saving and consumption reduction,and environmental protection.

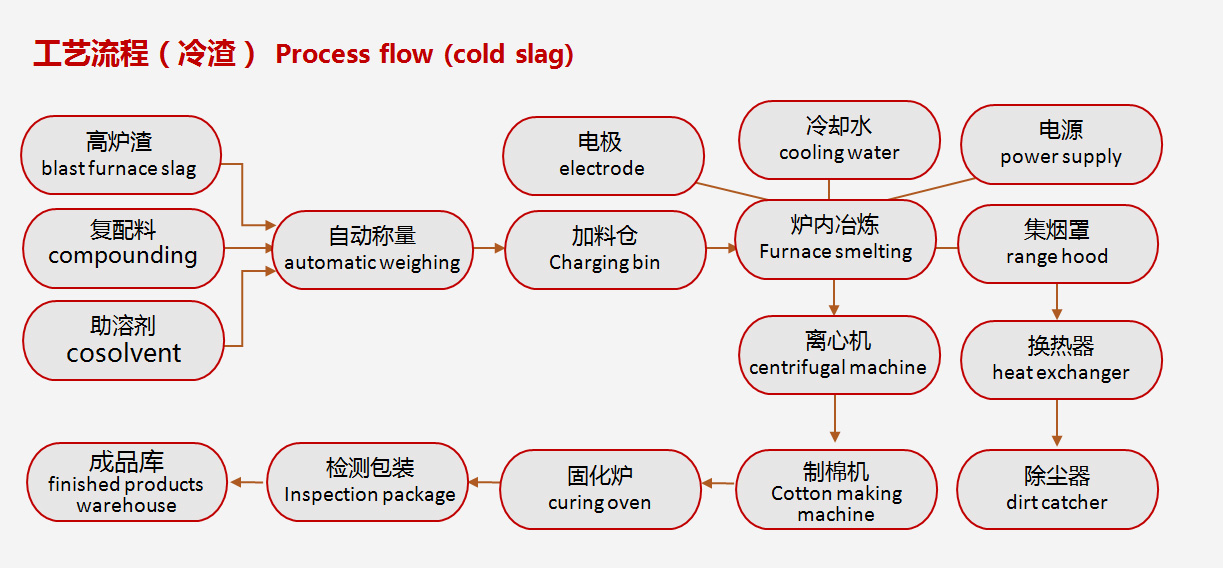

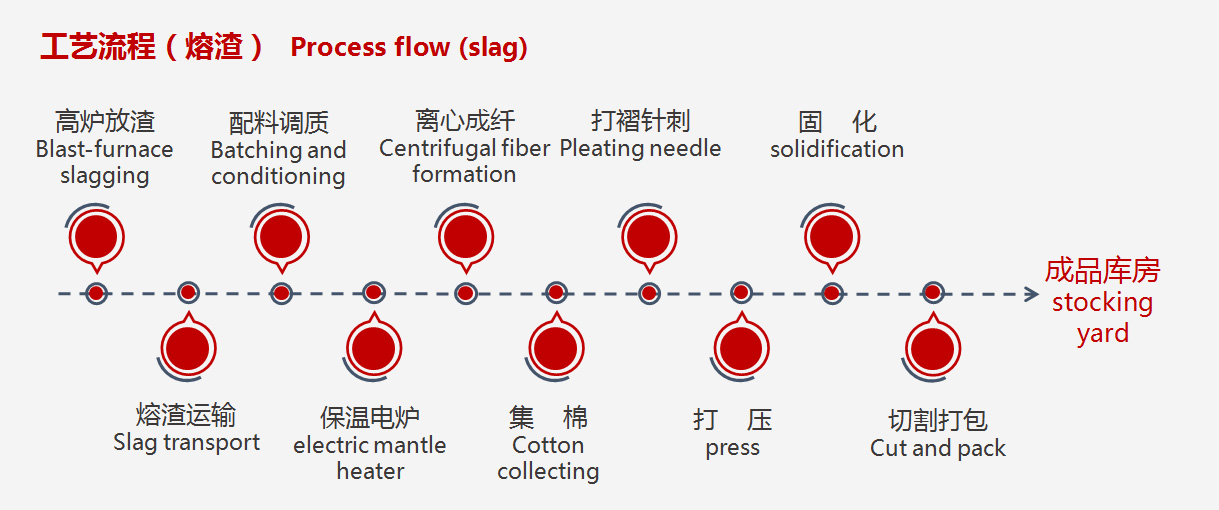

Process characteristics(molten slag,cold slag)

Make full use of sensible heat of slag,immersion induction heating saves smelting energy consumption and reduces production cost,and does not use coke at all.

Using electromagnetic stirring with lower frequency,the stirring intensity of molten pool can be increased to make the chemical composition of mineral wool melt tend to be uniform.

The temperature control is more accurate to ensure that the best conditions for fiber formation are met.

There is no pollution to the production environment.

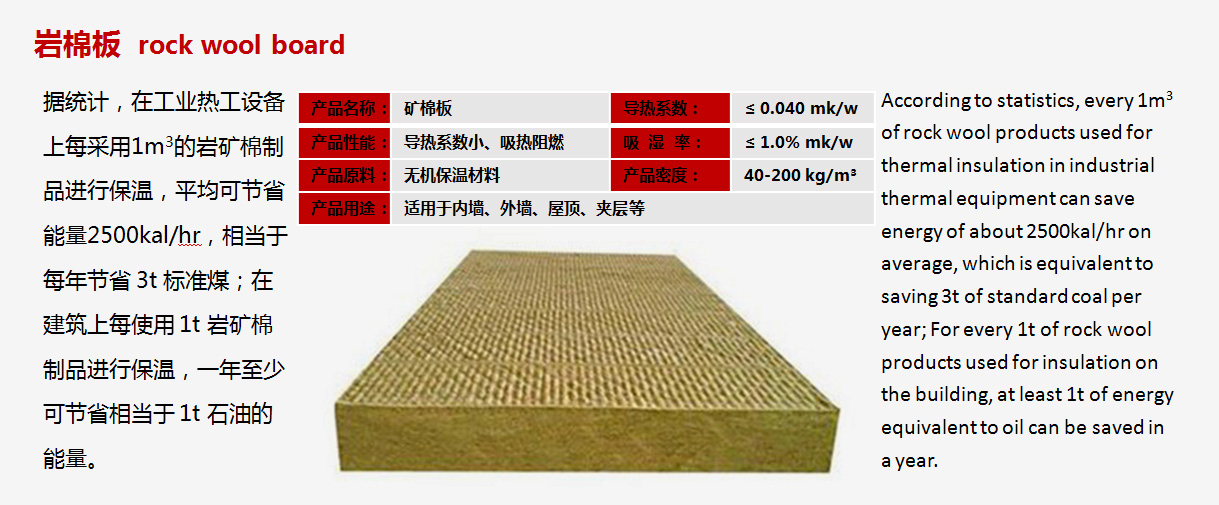

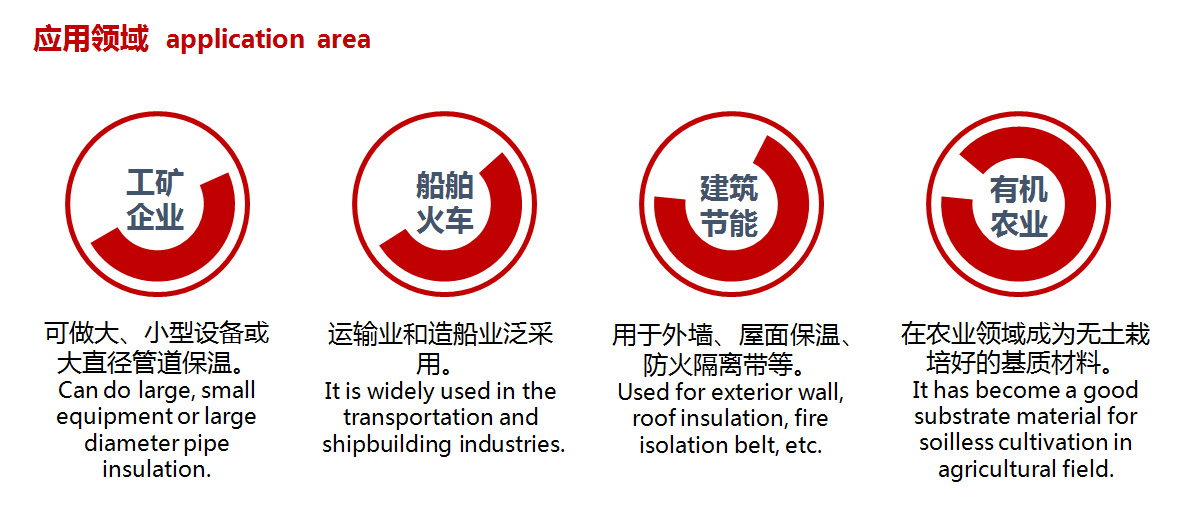

Product application:

social benefit

Annual production capacity of 10,000 tons to reduce the blast furnace slag discharge of 18,500 tons.

Save the power consumption of the water slag treatment system and save high system maintenance costs

Annual energy saving of 10,000tons of standard coal.

The annual water saving capacity of 10,000 tons is 0.45 million tons

Reduce non-renewable mineral resources by 10,000 tons

environmental benefit

The new technology of inorganic mineral fiber energy-saving materials with a capacity of 10,000 tons,compared with the existing cupola process technology of the same scale,can save about 2,500 tons of coke per year,reduce carbon dioxide emissions by more than 7,000 tons,reduce sulfur emissions by 21 tons,and reduce nitrogen oxides by 18.5 tons.

The capacity of 10,000 tons reduces water pollution by 0.4 million tons peryear.

The production capacity of 10,000 tons reduces solid waste emissions by 18,500 tons per year.

NEWS

NEWS

-

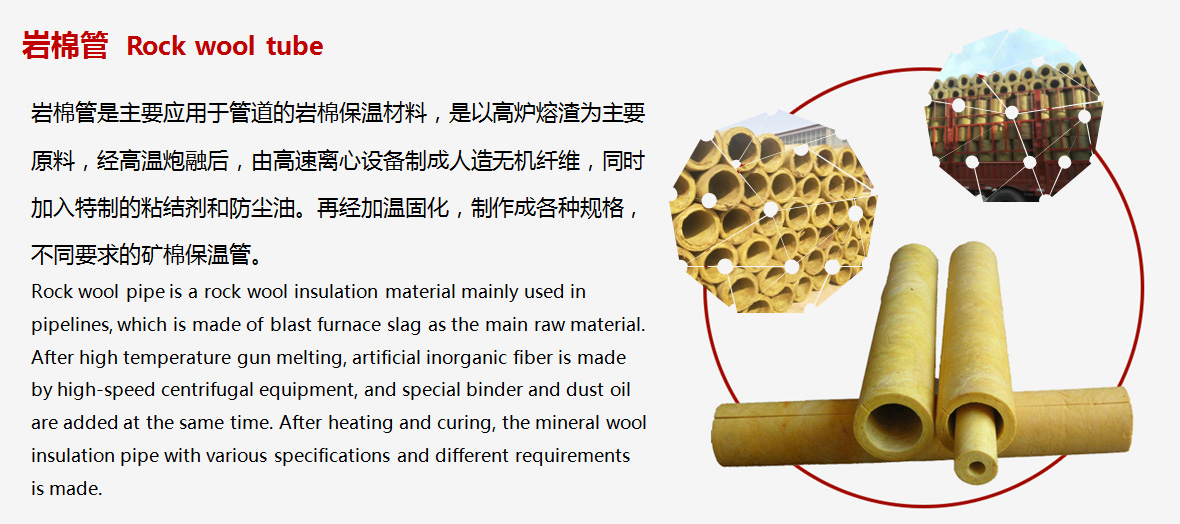

Tell me about the advantages and applications of rock wool pipes

2024-08-01 05:27:43

-

What should be noted when using rock wool boards?

2024-07-19 09:50:56

-

Analyze the characteristics of rock wool board?

2024-07-13 03:40:57

-

What are the main uses of rock wool boards?

2024-07-08 12:52:56

-

Have a brief understanding of the configuration structure of rock wool boards

2024-06-13 12:58:35

CONTACT

CONTACT

—— Tel:+86-13930107143

—— Contacts:Mr Wang

—— Add:Wei San Road South, Hope New Area, Mengcun Hui Autonomous County, Cangzhou City, Hebei Province